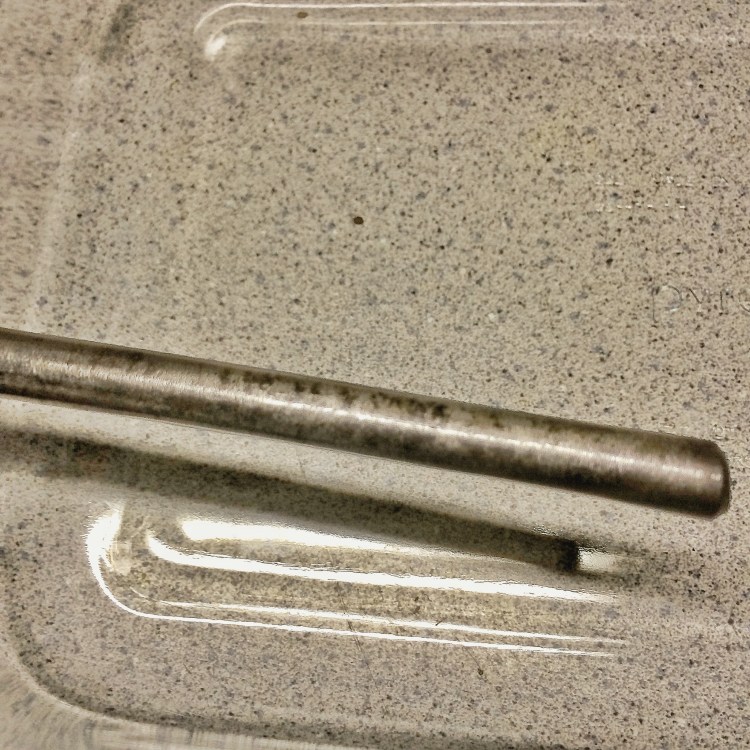

Do you guys remember the tool from this post?

Well, I got some advice as to how to get rid of the rust on it from a reddit reader (/u/TotaLibertarian) using an uncommon (and when I say that I mean totally common) substance.

It is suffice to say that my curiosity was piqued.

I did some investerating and research.

I combed over blogs and forums.

I wiki’d and googled until my eyes were crossed.

Then I experimented. First I sanded all the rust….

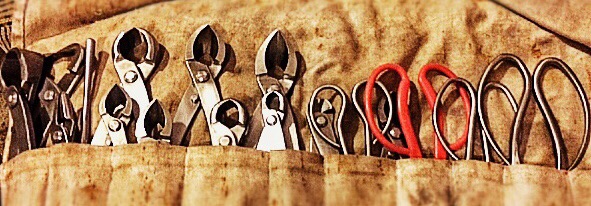

…. Both off the knife and also on a pair of root cutters.

Knife above, cutters below.

The rust on the cutters wasn’t too bad, it just kept coming back no matter how much I oiled it.

Next, the chemical….

After making a salad (with a little oil, salt and pepper) I put the two tools into a glass container (glass is important, so you don’t have any reactions with a metal container) and soaked them in straight vinegar for 36 hours.

What TotaLibertarian told me to use, which was not vinegar, has vinegar as an ingredient. But it’s not vinegar, per se, that is the desired chemical. It’s an acid that I needed.

Let me start at the beginning (and you thought I had done that already) and give you an idea of what I am doing.

First, go to your set of bonsai tools (not the stainless ones) and look at them. Notice the color: kind of a black color (except at the sharpened edge). We should all be aware that steel, or, more precisely, carbon steel, is generally silver in color. The problem with carbon steel is that it has a tendency to interact with oxygen molecules in the air and combine to form what is called…rust. We shall call it “red rust”, for reasons that I’ll explain in just a second.

There is another kind of rust that can affect carbon steel. It can be called “black rust” because it turns the silver carbon steel, well, black….ish. Sometimes it’s darker than other times (like my soul…..).

The acid combines with the steel in a similar way that oxygen does and could eat away at the steel the same way that red rust does. But you remove the corrosive chemical when you’ve achieved the desired effect and you end up with blackish steel. And the neat thing is, this coating prevents oxygen from getting to the clean steel and making red rust. Mostly.

This process here has a few names: bluing (in a professional capacity, like on a gun barrel), forced patina, poor mans rust preventative, experimental, blog subject process (I made that last up just now).

In industrial situations they can use, depending on how much money they want to spend, about 15 different chemicals and about the same amount of processes to achieve the bluing (how it went from being called black rust to blue I don’t know). They also use different temperatures, depending on the chemical used.

Since I’m a poor man, I shall use the chemical that is sitting on top of my refrigerator: vinegar. When a poor man does this to steel, they (of the ubiquitous kind) call it: forced patina.

Patina sounds better than black rust I suppose.

The simplest way to force a patina is to use an old chefs trick; say you have a hundred dollar, high quality and high carbon steel paring knife. Take a potato, stab the potato, and leave the knife stabbed in the potato overnight. You’ll get a nice charcoal colored patina the next day, and the resultant red rust protection. Some chefs will cut some lemons (or onions) and not clean their knife until the next day and get the same darkening.

It’s like science or something.

I decided to use vinegar because, like I said, it was sitting on my fridge, and I wanted to watch what was happening.

I like to watch…..

Can you see the bubbling?

I left the cutters in for the full 36 hours. The knife was only in for about 12 I think. I had other plans for it.

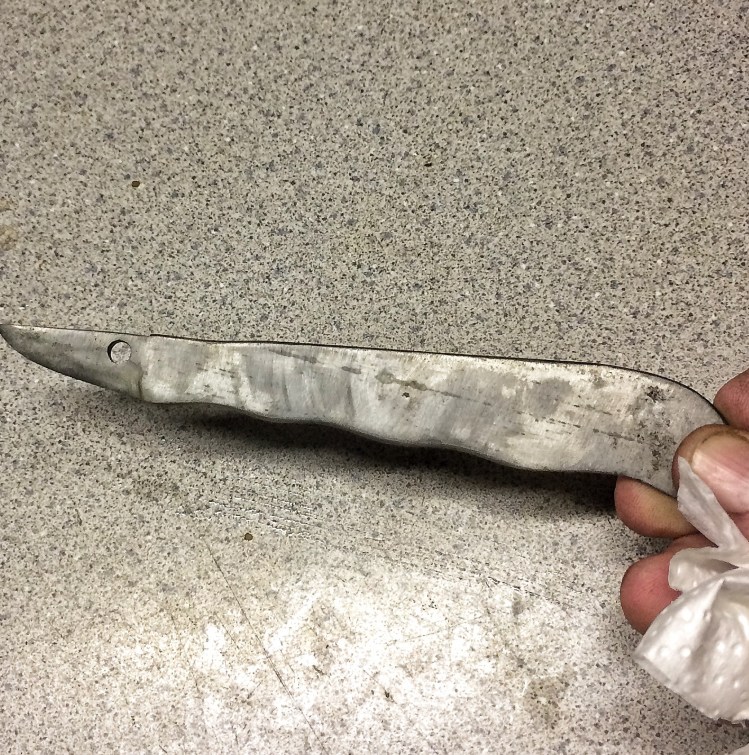

Wearing a “size-too-small” vinyl glove, I removed the cutters and wiped off the excess rust.

You can see the dull color above.

Below, the handle on the left has been wiped.

Then I washed it with dish soap and used some acetone to dry the water.

Not too bad, right? I’m not done yet.

The last step is to oil the tool to fix the patina and make it all glossy.

A wet, oiled-up tool looks so much sexier, right?

Here’s a comparison, an old knob cutter that’s almost at the end of its life and my newly patina-ed root cutter.

Don’t worry, I treated the old knob cutter as well later.

These root cutters came out nice, right?

There’s nothing like having a freshly oiled, 11 inch tool in your hand.

Makes you proud to be a man.

Anyway, back to the knife.

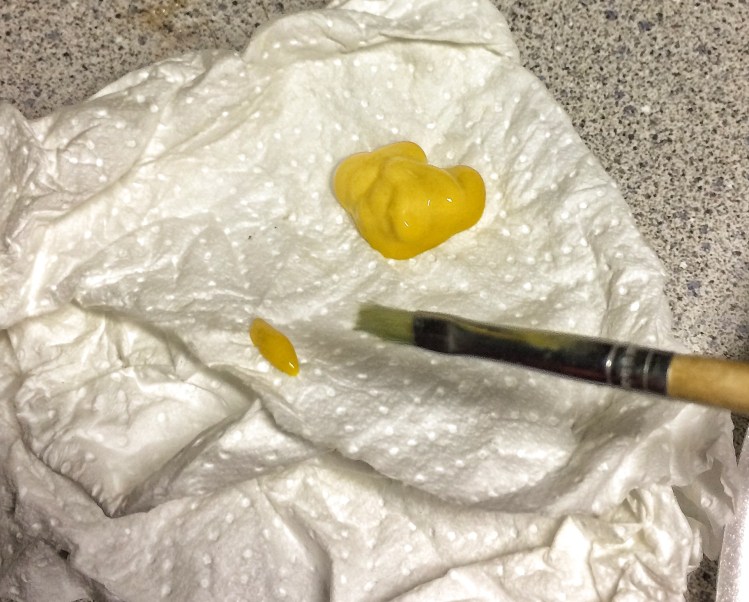

I wasn’t very happy with how light the patina came out on it, so I decided to use what TotaLibertarian originally said to use (before I got all clever and everything). He said to coat it in mustard.

Yep, mustard.

That’s my son Logan filling in as hand model. Look how dirty his hands are, I’m so proud. I had to wash off the bottle after I was done with the photoshoot.

I only took 15 pics to get the right lighting and angle. He was not pleased.

Go to the top of the blog, all the way to the title, read it.

Tiger stripes.

Oh yeah buddy!

Knife, patina forced, not very sexy.

Paint brush, mustard.

Some artistic brush strokes.

And, after only about four hours, and some scrubbing (mustard dries hard).

Cool! Way cool!

Now, it’s important to oil your steel after these processes. It stops the corrosion and fixes the patina.

And it keeps water off. This process makes the steel resistant to rust, but if you get water on it, it will still rust.

Water is the great equalizer: it wears down mountains, breaks levees, finds its way into any crack or crevice in a roof. Frozen water once covered 2/3rds of the world during the ice ages, grinding the land flat and scouring the soil away.

And i,t too, has oxygen (that’s the “o” in “h2o”) and will cause the dreaded red rust we’ve been fighting the whe blog post, like some creeping virus infecting the world, causing the zombie apocalypse and ending civilization as we know it.

And, after all your hard work, don’t forget and leave a tool out in the rain.

That’s the knob cutter I had treated.

And before you say,

“It was the cheap vinegar you used and your incompetence that caused the rust”

This is a “professional ” bluing job on a Japanese tool, left in the rain at the same time:

It’s almost like I was testing them or something.

I also experimented with boiling the vinegar on some other tools and got a somewhat darker patina. There are all these little tricks, different chemicals, different temps you can use to achieve the desired look. Play around with it. I had fun fooling around with the tools, annoying my family with the vinegar and mustard smells, especially when I was boiling it, and it gave me something to do while it was raining.

And just so I don’t get sued: use plenty of ventilation if you choose to boil your vinegar. Tools can be sharp, don’t cut yourself. And vinegar in a wound is not pleasant, or in your eyeball either, don’t say I didn’t warn you.

And, one last bit of advice: Oil your tool before you use it, it’ll be a lot more pleasant experience.

I’m a bit of a knife junkie too and have seen guys use the mustard to customize their knives. I haven’t tried it yet but it looks like you have motivated me to try my tools and make them my own. Awesome post…thanks!

LikeLike

if you had waited until Easter, you could have colored eggs and had a good excuse for boiling vinegar (maybe without complaints). And maybe created some interesting eggs too. Thanks for testing for us. Good modeling, Logan! I am sure Mama is proud too.

LikeLike

Reblogged this on Bonsai & Yamadori from Tony Tickle and commented:

Love this from Adam… now… I hope Carolyn does not miss the vinegar

LikeLike

Great blog post Adam, Got to share this one too.

LikeLike